At A.B Enterprises, we are having fully equipped machinery & techniques of doing production by our skilled technicians & artisans. We offer complete 100% in-house production with the processes and respective machinery described below.

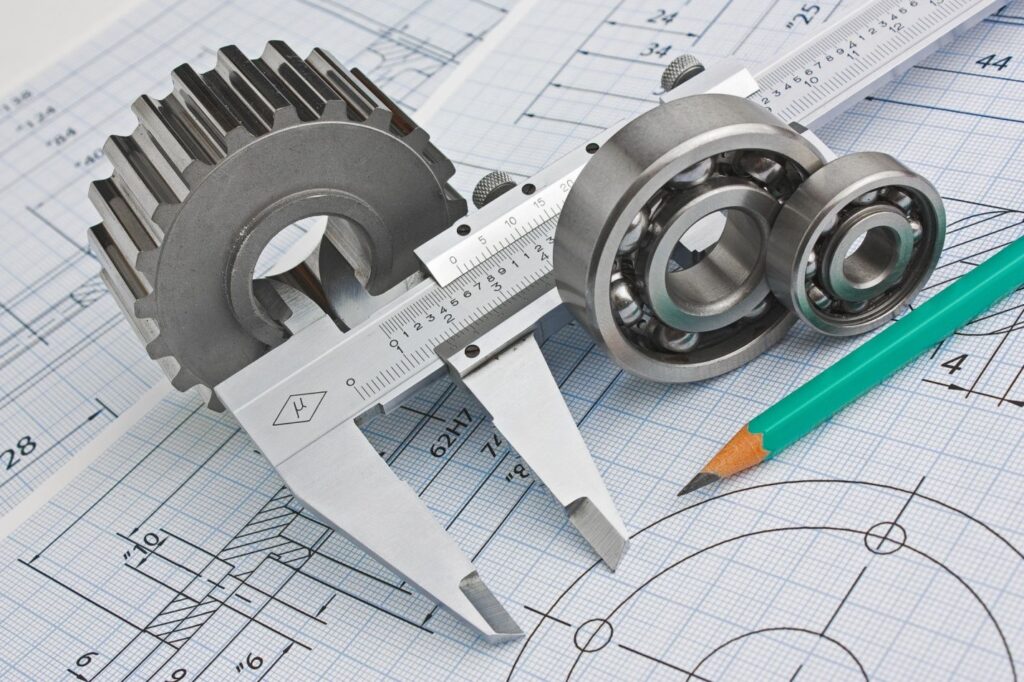

DESIGNING PROCESS

Design and pattern of the product are made at this initial process of manufacturing. For this process, we have a dedicated team for designing, pattern making, and developing products. After this process, the manufacturing/production process starts.

PRODUCTION PROCESS

For our Metal Products:

- Sand Casting by Hand

- Filing, Grinding, Drilling, Lathe, Milling,Taping, Lancer and Power Press Machines.: These machines convert the metal product to standard form from their base form.

- Shot Blasting Machine: Shot blasting is used for clean and remove grind marks from cast iron products.

- Tumbling Machine: It is used to again clean and make shiner iron products.

- Finishing Plant:Polishing with several finishes like Copper Antique, Brass Antique, Pewter, Antique Oil, Chrome, Nikel, Gold and many more all are available in our finish page.

- Electrostatic Lacquer Machine:Lacquer is applied on the required Products.

- Powder Coating Machines : Powder coating is done in colours like Black, Brown, White and also in Black & Brown Matt Texture.

For our Ceramic Products:

In this there are many processes done by hand as compared with machinery that’s the main reason these Products are known as Handicraft Products.

- Collection and Composition of Ceramic Mud: Collection & composition mixing of several natural stones and clays to make ceramic mud.

- Grinding of Ceramic Mud: Grinding of ceramic mud on a ball mill machine.

- Drying , filtering, and Grinding again in small form to make a complete ceramic mud.

- Die Press Machine: Mould is fixed in the machine and casting starts to make ceramic products like ceramic knobs.

- Surfacing: Surfacing is done by hand with water on products to remove unwanted mud from the products.

- Initial Firing: First stage firing is done at 800 degree celsius to 900 degree celsius at first round in firing tunnel machine.

- Surfacing: Surfacing is done again one more time after firing to make the product more smooth.

- Hand Painting: Hand painting is done by our artisans beautifully on product.

- Transparent Glazing: Glazing is done by glaze solution made up of several chemicals.

- Final Firing: Final firing is done at 1100 degree celsius to 1200 degree celsius for 24 hours in a firing tunnel machine. After that products are completed and ready for the next process.

Packaging Process

We use multiple packaging processes to ensure safe delivery and can also develop customized packaging as per buyer specifications.

Polybags (Export quality)

Plain Box (White & Brown)

Description Header on Polybags

Description Header on Boxes

Bubble Poly Bags

Barcode Label (barcode provided by buyer)

Customized Boxes of the Buying Company

Strip and Clamp Sealing on Large Boxes

After these processes, goods are stocked in our warehouses and made ready for shipping.